Published in Scientific Papers. Series "Management, Economic Engineering in Agriculture and rural development", Vol. 18 ISSUE 1

Written by Adelaida Cristina HONȚUȘ

The purpose of this paper is to present and maintain that the use of bricks, by brick ceramic blocks as a building material, is still the best option to have a durable and durable house. I have presented both the advantages and drawbacks of using ceramic blocks in the execution of buildings. As a method of research, we presented the technological method of execution of masonry blocks in ceramic blocks and the method of realization of ceramic blocks. The building material, its quality, how it is used, and the cost of each construction material are very important in the execution of a home. We can say that a brick house can last for over 150 years. The lifetime of a brick house is high and the maintenance costs are very low. Even if we see that most old homes have used full brick, it is not as resistant as the Porotherm ceramic blocks. The technology through which they are made is far more advanced than what was available in the past. Ceramic brick blocks are baked at particularly high temperatures and robotic formats with a high degree of precision. Thus, although they have air inlets for better thermal insulation, they are particularly resistant to compression. The field of brick production is constantly evolving. Increasing demands on structural properties and economic issues lead to product differentiation and specialization. For these reasons, we conducted this study on all aspects, both technical, technological, and economic, regarding ceramic brick blocks.

[Read full article] [Citation]

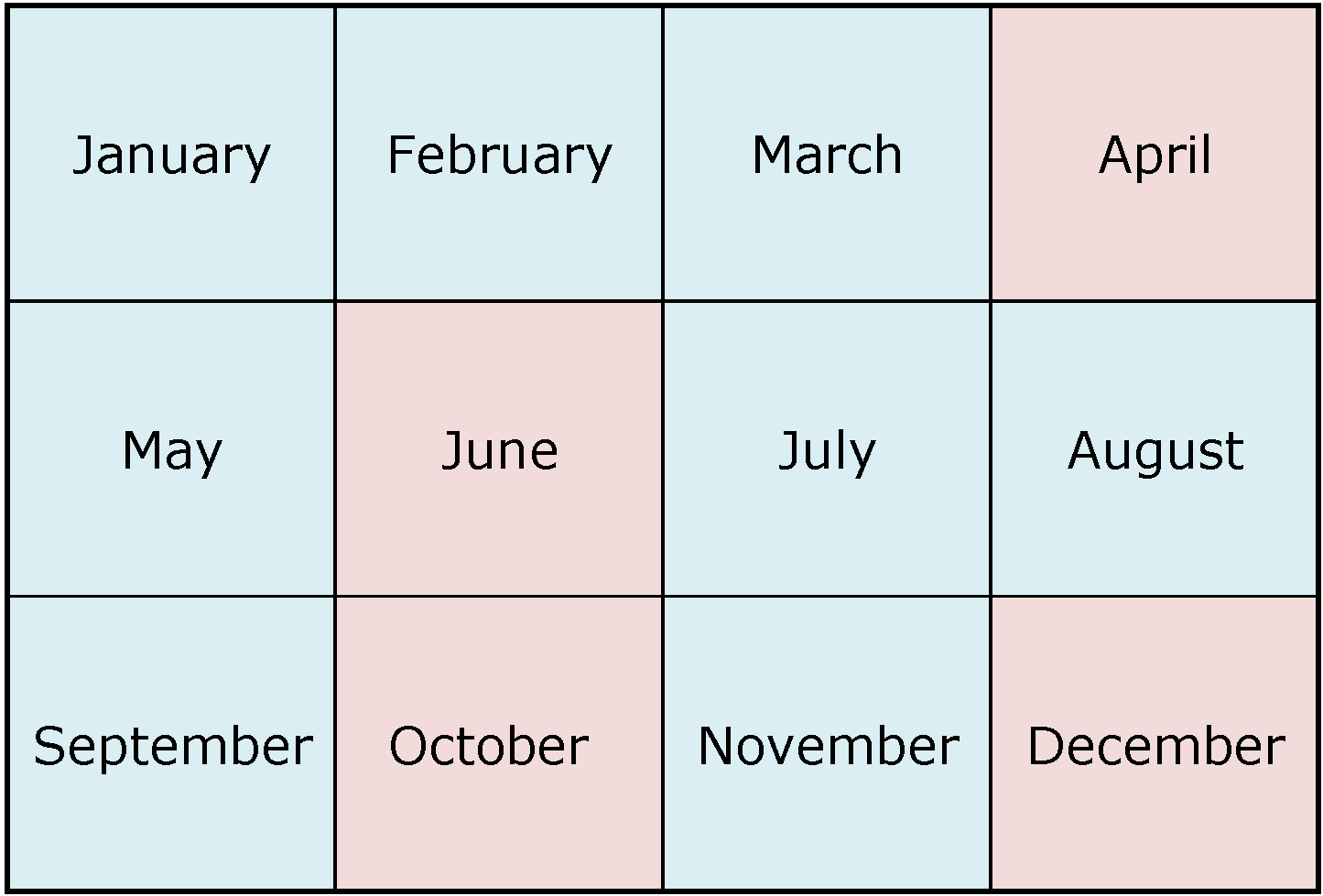

Next Issue will be published according the the calendar.

Next Issue will be published according the the calendar.