Published in Scientific Papers. Series "Management, Economic Engineering in Agriculture and rural development", Vol. 21 ISSUE 1

Written by Tarek FOUDA, Mohamed EL-KHOLY, Adel ELMETWALLI, Mohamed DARWESH, Amal EL ZANATY

The aim of this research was to investigate the efficiency of cold pressing and low temperature techniques to produce oil and cakeform flax seeds. Also, to evaluate the performance of the oil press machine and discuss cold press extraction is one of the methods of mechanical extraction as well as required less energy than other oil extraction techniques and also environmentally friendly. The samples were used from fresh flax seed weighted as a amount of feeding at 1, 2, 3, 4 and 5 kg at 12% db moisture content. The results with cold pressing showed according feeding ratio increased from 20, 40, 60, 80 and 100 %. operation time increased to 8, 16, 23, 32- and 38- min. addition to the temperature start at 29°C. and increase by 31, 34, 35, 36 and 370C. Also, the oil product increased by 184, 402, 576, 775 and 981g. Cake product increased by 786, 1,576, 2,351, 3,196 and 3,991g. While with low temperature techniques using heater start temperature at 47°C for all the samples the feeding ratio increased from 20, 40, 60, 80 and 100 %. the extraction time increased from 6, 12, 18, 24 and 30 min. The oil product increased by 187, 388, 581, 783 and 991 g., cake product increased by 800, 1,591, 2,394, 3,191 and 3,900 g. according feeding ratio increased from 20, 40, 60, 80 and 100 %. but the temperature decreased from 43, 42, 41, 40 and 39°C after using cold pressing and low temperature techniques the oil quality have high contents of functional EPA (20:5 ω 3) and DHA (22:6 ω 3) for oil flax cake. Also, oxidizability index was 1.318.

[Read full article] [Citation]

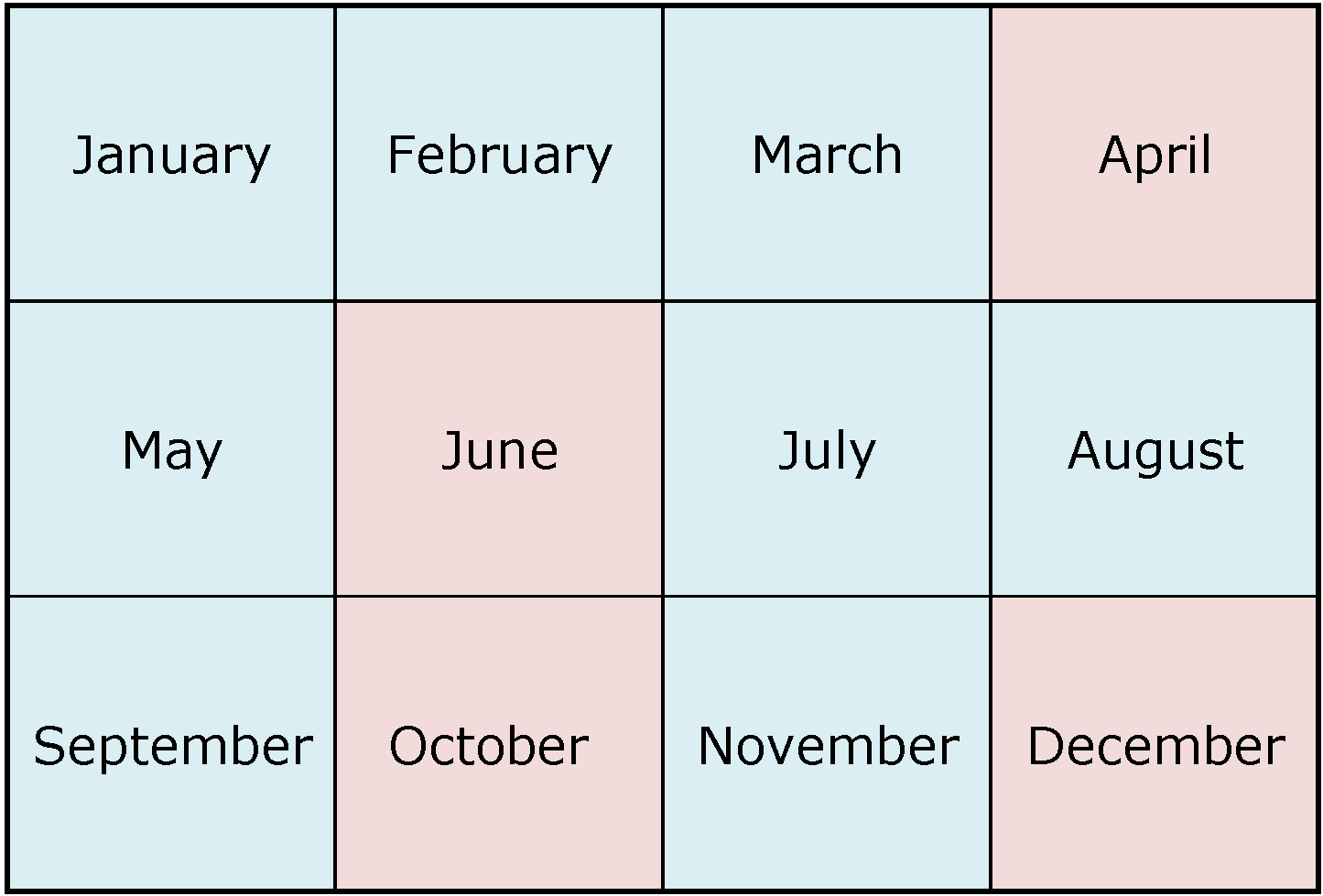

Next Issue will be published according the the calendar.

Next Issue will be published according the the calendar.