Published in Scientific Papers. Series "Management, Economic Engineering in Agriculture and rural development", Vol. 22 ISSUE 3

Written by Tarek FOUDA, Mohamed EL-KHOLY, Summer SHAMALA, Mohamed GHONAME, Shimaa SALAH

In this study, the combined infrared-hot air dryer develops and optimize in Agricultural Engineering laboratory, faculty of agriculture, Tanta University, Egypt. Thin-layer modelling of sweet potato slices drying under infrared (IR) and hot-air drying (HAD) were used to estimate the drying coefficients. The initial moisture content of the freshly harvested sweet potato was 79 – 81 % (w. b.). Three different levels of sweet potato slices thickness (1, 3, 5 mm), were pre-treated by dipping into a solution of 0.5 % sodium meta-bisulphite and 1% citric acid for 30 min. Four different levels of infrared radiation (0.861, 0.973, 1.039 and 1.161 kW.m-2) and three different levels of air-drying temperature (45,55 and 65°C) with a constant air velocity of 1.2 m. s-1 were using. The experimental measurements included sweet potatoes slices moisture content, air temperature, radiation intensity, and quality changes of the dried sweet potato. Three different thin layer drying models (Lewis's model and Henderson & Pabis's and Logarithmic model) were examined for describing the changes of moisture content during the drying process. The results show that, the Coefficient of determination R2 and Standard error, SE. for The Logarithmic model recorded R2= 0. 99 and SE= 0.122 were considered more proper for describing the drying kinetics and predicting the changes in moisture content of sweet potatoes more than the Henderson and Pabis's were model recorded R2= 0.94 and SE= 0.51 and Lewis's model were recorded R2= 0.96and SE = 0.241. The results show that, the moisture ratio of sample slices decreased when the radiation intensity and the drying air temperature increased. Meanwhile, the drying constant of Logarithmic model (kLog) increased with the increasing of radiation intensity and air-drying temperature and the decreasing of slice thickness. The diameter and thickness shrinkage percentage occurred with all treatments, while slightly increasing with infrared radiation. The rehydration ratio ranged from 3.95 to 5.53.

[Read full article] [Citation]

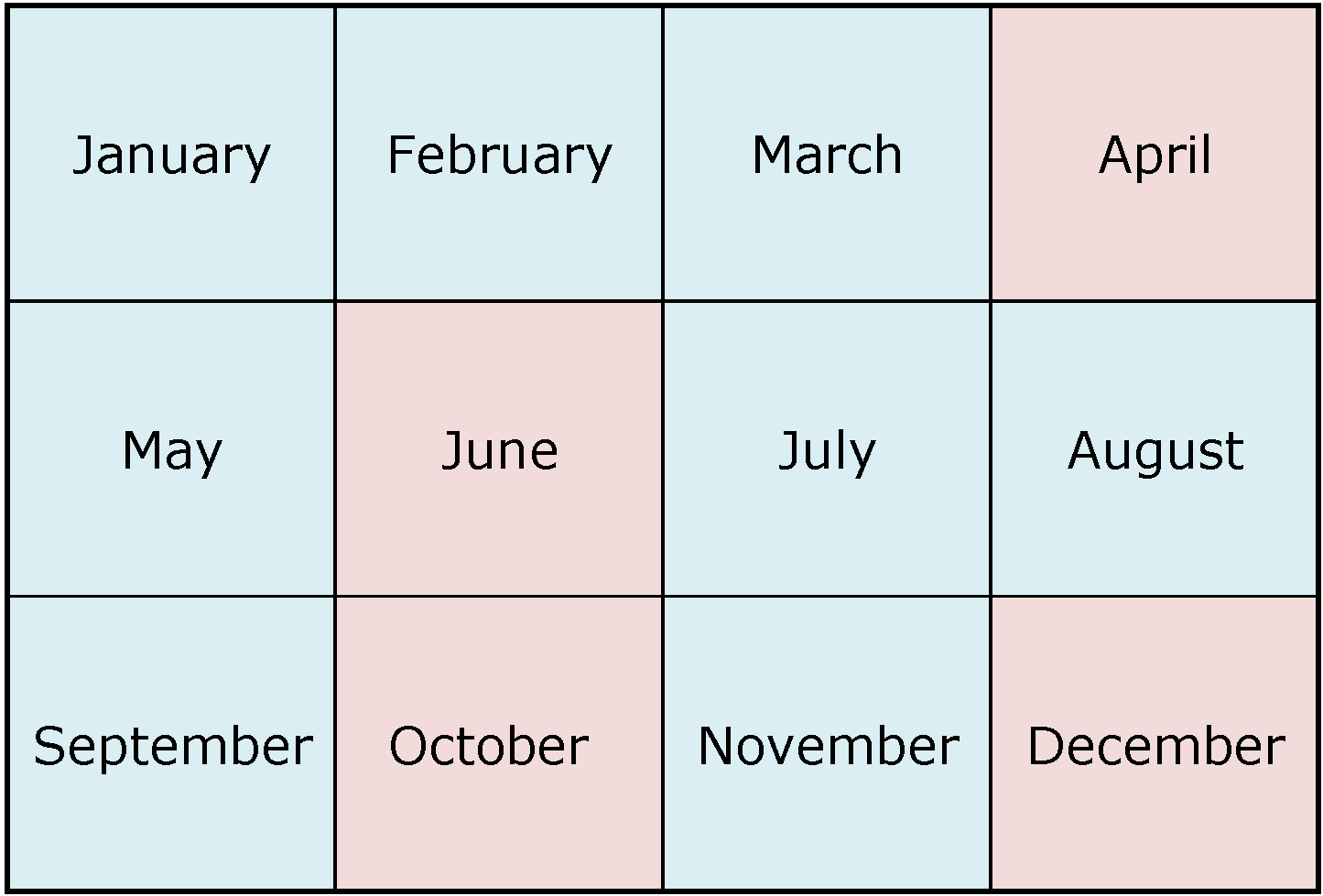

Next Issue will be published according the the calendar.

Next Issue will be published according the the calendar.