Published in Scientific Papers. Series "Management, Economic Engineering in Agriculture and rural development", Vol. 17 ISSUE 2

Written by Vecdi DEMİRCAN, Mehmet Ali KOYUNCU

The objective of this study was to carry out an economic comparison of different types of cold storage facilities for apple. Primary material of the study was comprised of original data acquired from cold storage facilities in Isparta province which is ranked number one in Turkey in the field of apple storage. Analyses were carried out by classifying the enterprises into three groups according to their cold storage types as those with normal atmosphere (NA), those with controlled atmosphere (CA) and those as cold storage facilities with a mixture of normal and controlled atmosphere (NA+CA). It was determined that the average capacities were 7,500 tons, 4,540 tons and 2,400 tons, respectively for NA+CA, NA and CA facilities. Capacity usage ratio was determined as 85.42% for CA facilities, 79.74% for NA facilities and 77.60 % for NA+CA facilities. It was determined that Golden Delicious ranked first among the apple types stored in all cold storage types. It was determined that the ratio of Golden Delicious among the apples stored in the facilities was 52.49 % for NA, 52.89% for NA+CA and 69.86 % for CA facilities. NA+CA facilities were determined to have the highest average annual operating cost among the examined facilities. Average total cost per enterprise among NA+CA facilities was determined as 355,869 USD, 192,131 USD for NA facilities and 121,282 USD for CA facilities. When the enterprises were compared with regard to net income per ton, it was observed that CA cold storage facilities were more profitable. Net income per ton was calculated to be 27 USD for CA facilities, 21 USD for NA+CA facilities and 17 USD for NA facilities. It was determined that total costs and total income were equal and that break-even point was reached when 41.62% of the capacity is used for CA cold storage facilities, 43.94% for NA+CA facilities and 45.75% for NA facilities. Facilities make profit after this point.

[Read full article] [Citation]

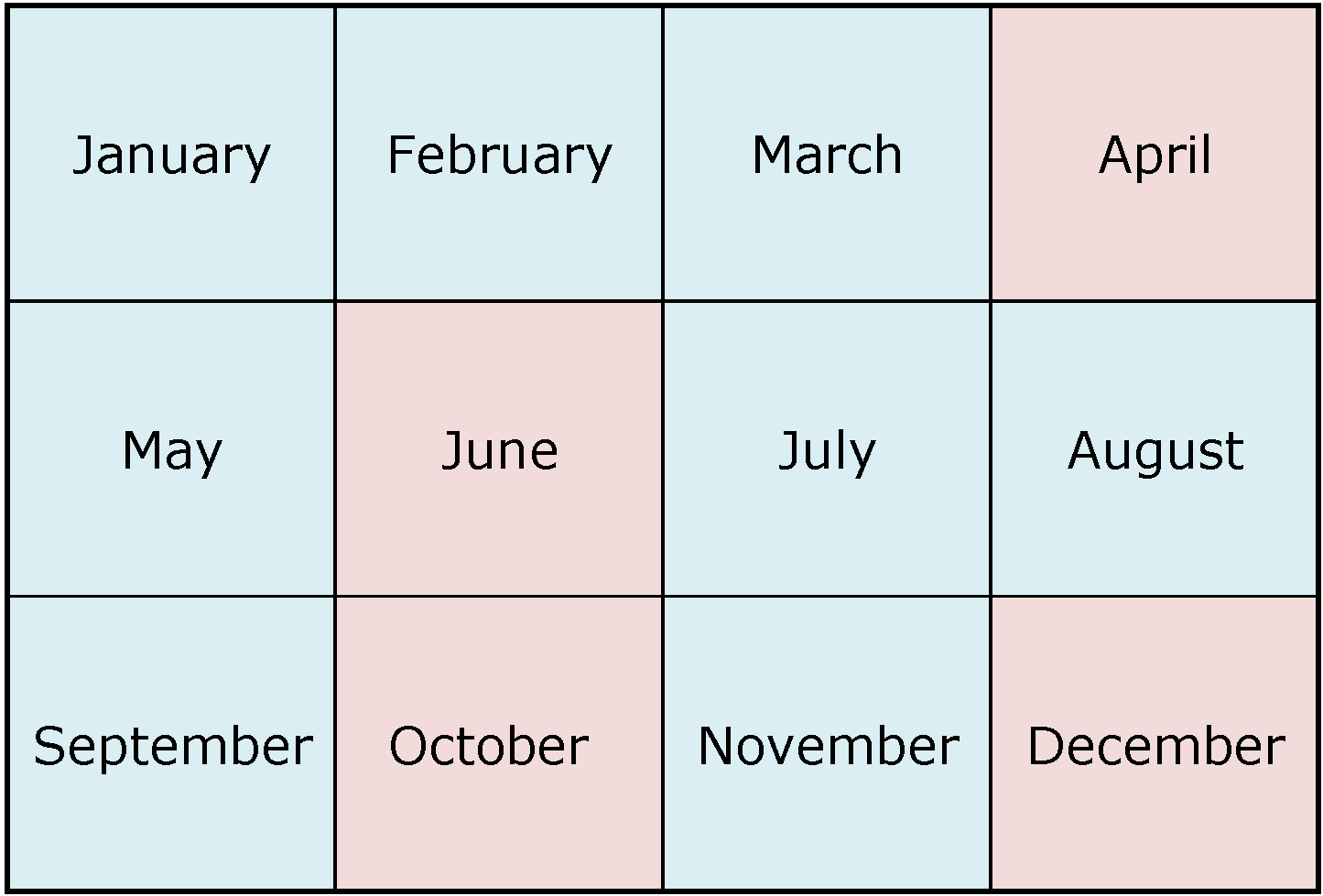

Next Issue will be published according the the calendar.

Next Issue will be published according the the calendar.