Published in Scientific Papers. Series "Management, Economic Engineering in Agriculture and rural development", Vol. 21 ISSUE 1

Written by Tarek FOUDA, Osama BAHNAS, Mohamed SOLTAN, Mohamend GHONAME

The auxiliary roll of the rice combine harvester were developed and manufactured from local material to reduce wearing rate for threshing device also minimize fuel consumption and energy requirements. Replacing auxiliary roll knives arranged in a spiral instead by forks separating on length were 90 cm with seven rows and each row has four blades to increase the efficiency of separating the seed. The measurement indices of the auxiliary roll before and after development were threshing efficiency, threshing capacity, fuel consumption, power required, energy requirements, device mass losses percent, wearing rate, wearing resistance, critical wearing value, specific wear and expected life. during the harvesting operation of rice crop the rustles showed It is recommended to use the knife as a threshing device because auxiliary roll threshing efficiency increased by 0.2% threshing capacity increased by 16.83 %, fuel consumption decreased by 0.16 %, power required decreased by 0.15 %, energy requirements decreased by 0.33 % device mass losses percent decreased by 1.4 %, wearing rate decreased by 0.11 % wearing resistance decreased by 0.12%. critical wearing value increased by 34 %, specific wear decreased by 25 % and expected life increased by 78.60% all this result tested after 500h operating time.

[Read full article] [Citation]

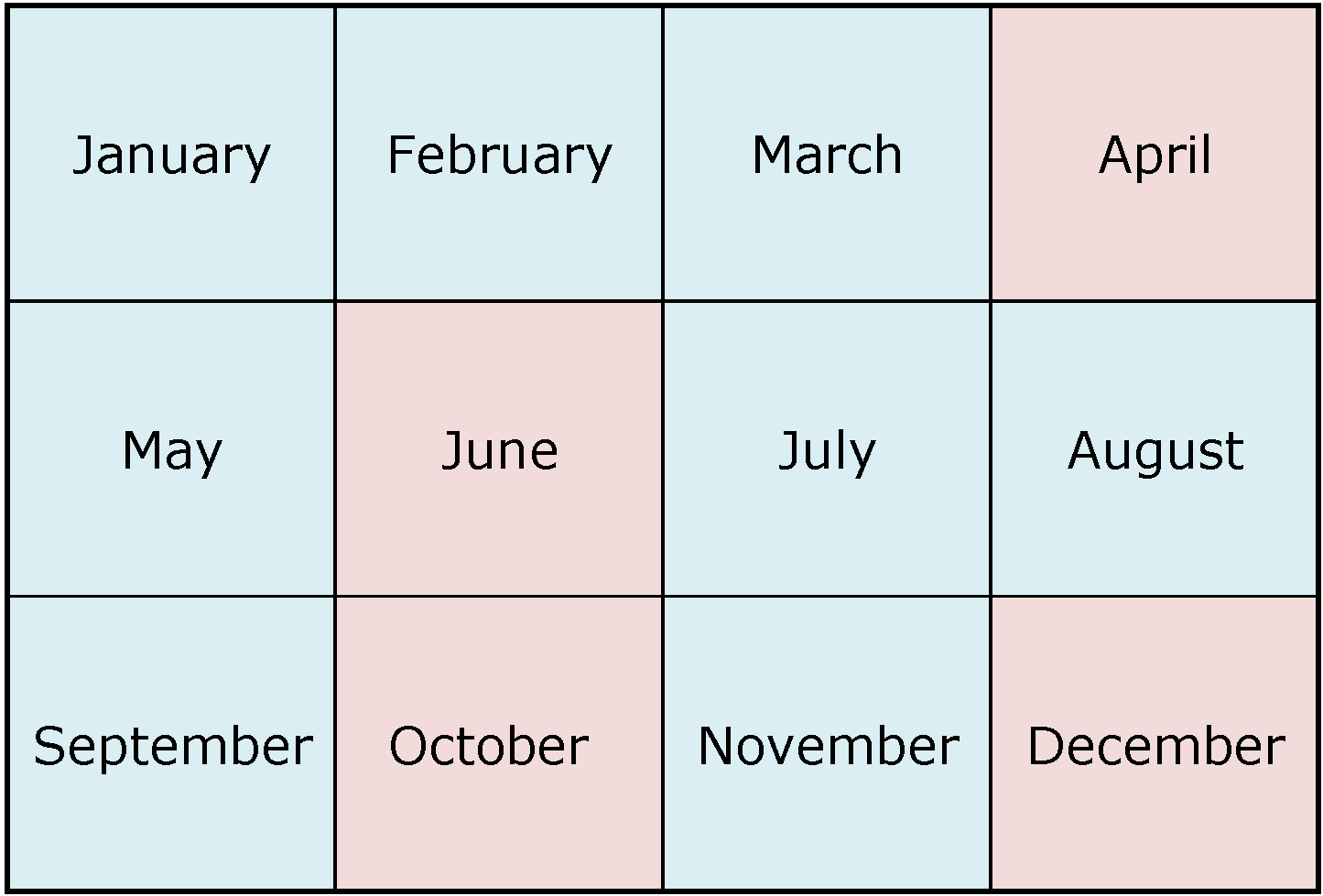

Next Issue will be published according the the calendar.

Next Issue will be published according the the calendar.