Published in Scientific Papers. Series "Management, Economic Engineering in Agriculture and rural development", Vol. 25 ISSUE 3

Written by Kareem ALHAMSHARY, Rashad HEGAZY, Tarek FOUDA

Unite Finite Element Analysis- FEA model has been developed containing material properties, loads, fixtures, constraints and connections among all parts, faces and edges of the suspension system components. FEA analysis showed that U-bolt is a critical component of this suspension system. Simulation study analyzed both U-bolt diameter and doubling the Quantity of U-bolts from four to eight U-bolts. Von-Mises stresses, displacements and Shear stresses have been monitored and analyzed. U-bolt diameter has gradually increased with 2mm steps from 20mm to 22mm to 24mm for a first configuration with four U-bolts and second design configuration with eight U-bolts. Taking into consideration available materials, manufacturing methods and cost in Egyptian market showed that using the first design configuration with four U-bolts of 24mm diameter decreased the maximum von-Mises stress, displacement and shear stress on the U-bolts from 775 to 547 MPa, 4 to 2.4 mm and 335 to 222 MPa respectively instead of using the same configuration with 20mm diameter U-bolts. A more durable option is using the second design configuration with 24mm diameter U-bolts which decreased the maximum von-Mises stress, displacement and shear stress on the U-bolts from 775 to 321 MPa, 4 to 2.19 mm and 335 to 108 MPa respectively. The results showed the importance of CAD software for improving the design process of the suspension system with minimum cost and time. Also, the effects of using thicker U-bolts and doubling their quantity were noticeably observed. The allowable shear stress of the U-bolt material is 254 MPa, after running FEA analysis the maximum shear stress on U-bolts has been reduced to 222 MPa and 108 MPa for both design configurations and the shear stress ratio were 0.874 and 0.425 respectively which make both design configuration safe for operation. The total cost of imported bogie suspension system worthed 3,447 US dollars. while the total cost of the local manufactured bogie suspension system for the 1st consideration and 2nd consideration were 3,257.4 and 3,358.6 US dollars respectively. The local component percentage of the local manufactured bogie suspension system for the 1st consideration and 2nd consideration were 51.602% and 53.06% respectively.

[Read full article] [Citation]

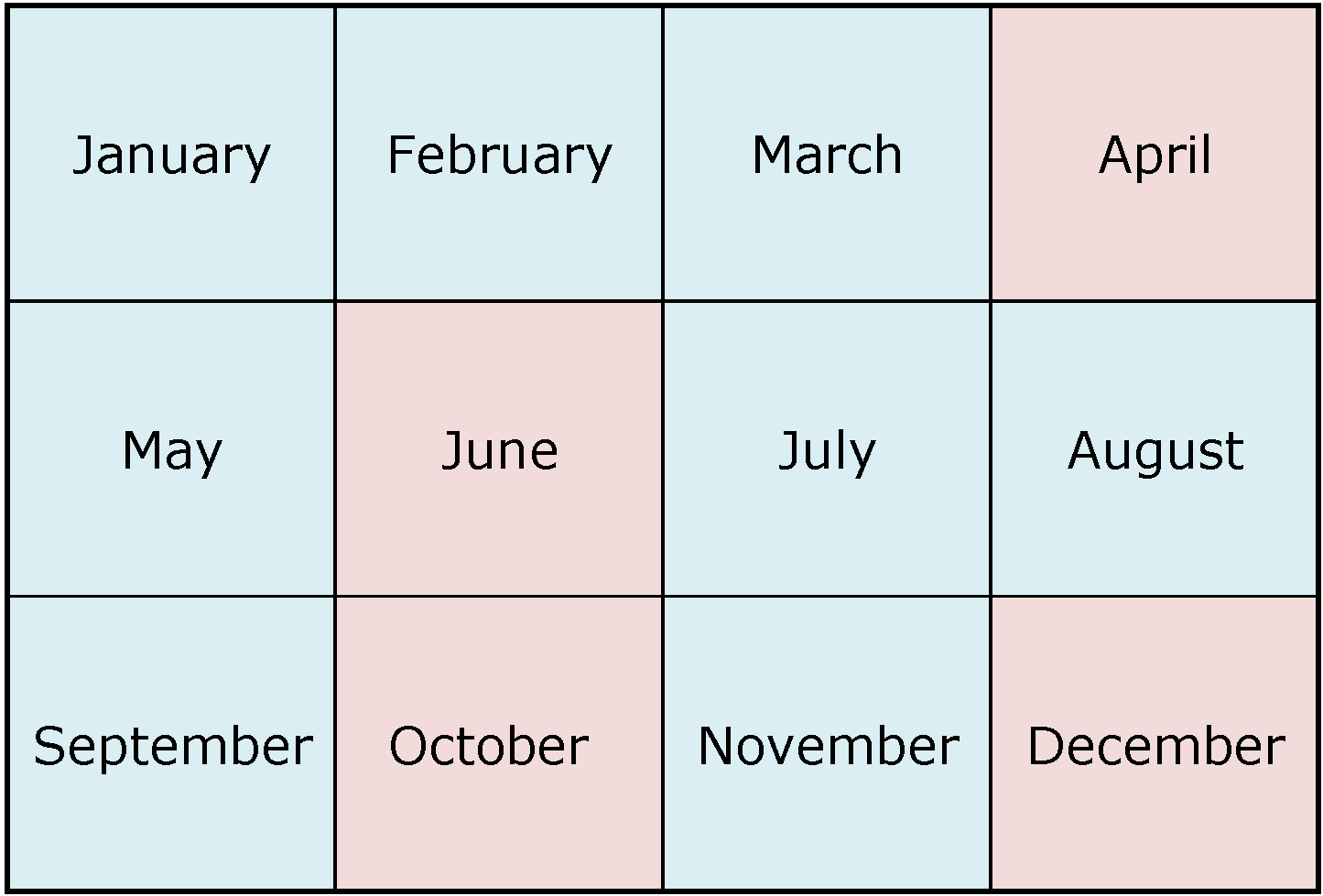

Next Issue will be published according the the calendar.

Next Issue will be published according the the calendar.