Published in Scientific Papers. Series "Management, Economic Engineering in Agriculture and rural development", Vol. 25 ISSUE 3

Written by Jamel SALO, Severino Jr. SALERA, Grace SALO, Erwin LUDEVESE, Imelida TORREFRANCA

High-capacity shellers equate to high initial investment costs, unsuitable for most local mung bean farmers. This study developed a shelling cum cleaning machine to address the need for small-scale mung bean production. The design was registered in the Intellectual Property Office of the Philippines (IPOPHL) with a registration number of 3/23/051293. The machine performance was evaluated using speed and pod moisture content variations. Speed variations in the shelling and cleaning assembly were achieved using different pulley sizes at the shelling shaft, while moisture variations were tested using the oven-dry method from newly harvested and air-dried pods. It also assessed the economic performance of the machine to determine what ownership scheme is best for the farmers. It was concluded that satisfactory performance was obtained using a shelling speed of 600 rpm and 12% moisture content. The machine has an input capacity of 64.24 kg/hr, shelling capacity of 30.99 kg/hr, shelling efficiency of 97.84%, blower and separation efficiency of 95.51%, blower and separation losses of 5.29%, and unshelled losses of 2.16% and was affected significantly by the pod moisture content. The mechanically damaged kernel is 1.79% and is affected by both the speed and pod moisture content variations. On the other hand, the shelling recovery, scattering losses, and output purity are 91.01%, 1.53%, and 98.35%, respectively, and were not significantly affected. The machine cost is ₱14,675.00, and the operating cost is ₱0.80/kg. Considering a payback period of 1 year, processing 10,411 kg of inputs will break even all the costs at a custom rate of ₱1.00/kg.

[Read full article] [Citation]

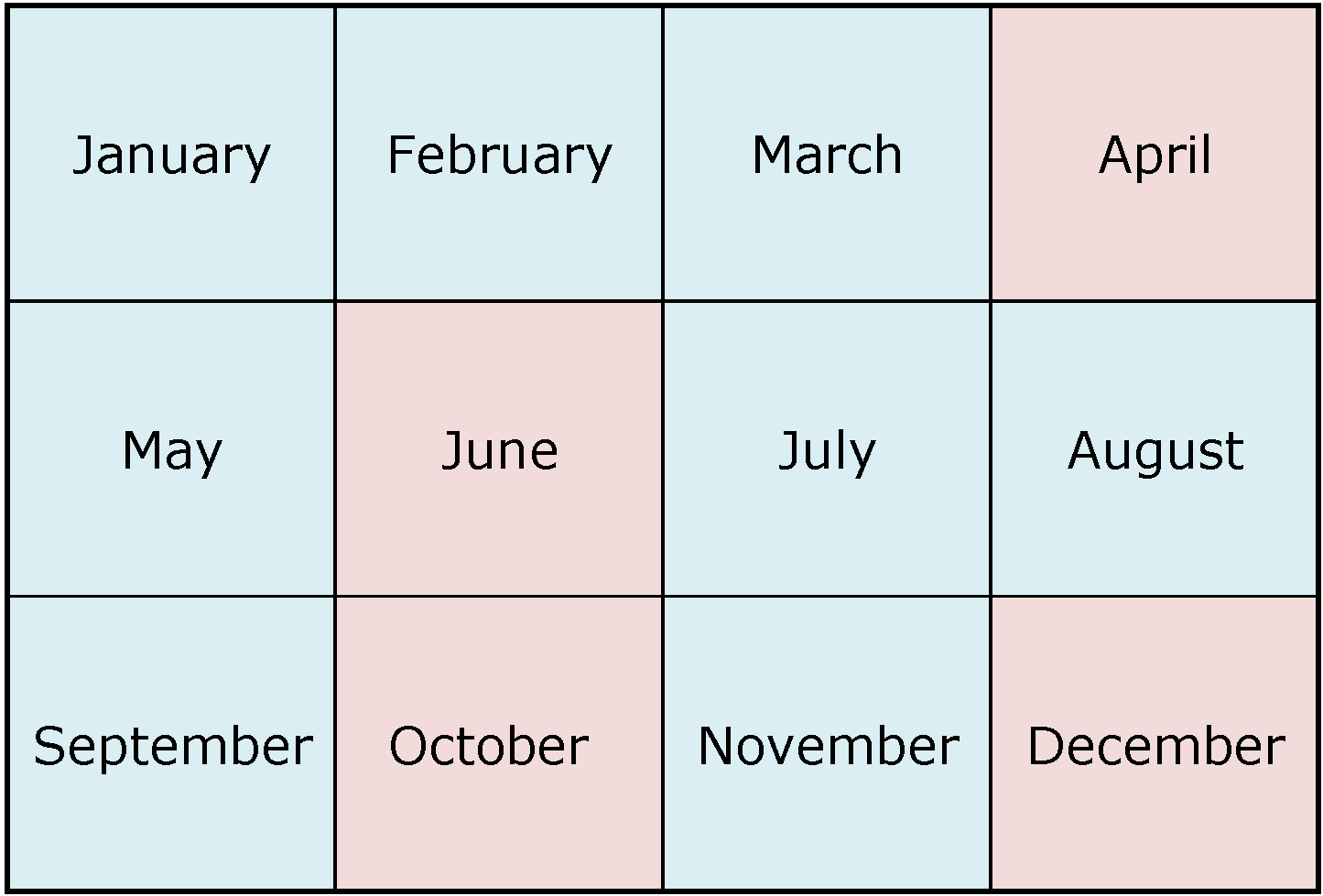

Next Issue will be published according the the calendar.

Next Issue will be published according the the calendar.