Published in Scientific Papers. Series "Management, Economic Engineering in Agriculture and rural development", Vol. 24 ISSUE 3

Written by Tarek FOUDA, Nourhan KASSAB

This paper presents a possibilities of infrared thermography especially focused on temperature measurement as a non-destructive to monitor temperature profile during potato frying With using three different, easily accessible skillet materials stainless steel Wock Skillet, Stainless steel with PTFE polytetrafluoroethylene material and Tefal Skillet. The thermal imaging cameras and software to read skin surface temperature and calculate an estimated core body temperature. The results recorded the internal and external temperatures at the three Skillet materials, the temperature of air, oil, fire, and potatoes, for the Wock Skillet before frying 29.8, 36.9, 21.7, 45.9, 216.7 and 17.2Co while after frying 50.9, 61.9, 23.1, 111.9, 204 and 31.8 Corespectively. as they were for the Teffal Skillet before frying 131, 154.9, 25, 94.2, 206.1 and 17.2 Cowhile after frying 200.7, 201.3, 27.8, 161.1, 260.7 and 40.1Co respectively. as they were for the Wock Skillet before frying 59.7, 51.6, 26.7, 65.6, 129.8 and 17.2Co while after frying 99.4, 126, 28.8, 120.1, 197.4 and 35.1Co respectively. Therefore, the best temperature profile of frying with typesSkillet for the least heat emission, and the lowest temperature recorded for oil and potatoes, were in the Wock Skillet, followed by the Teffal Skillet, and finally the EL RAMLAY Skillet.

[Read full article] [Citation]

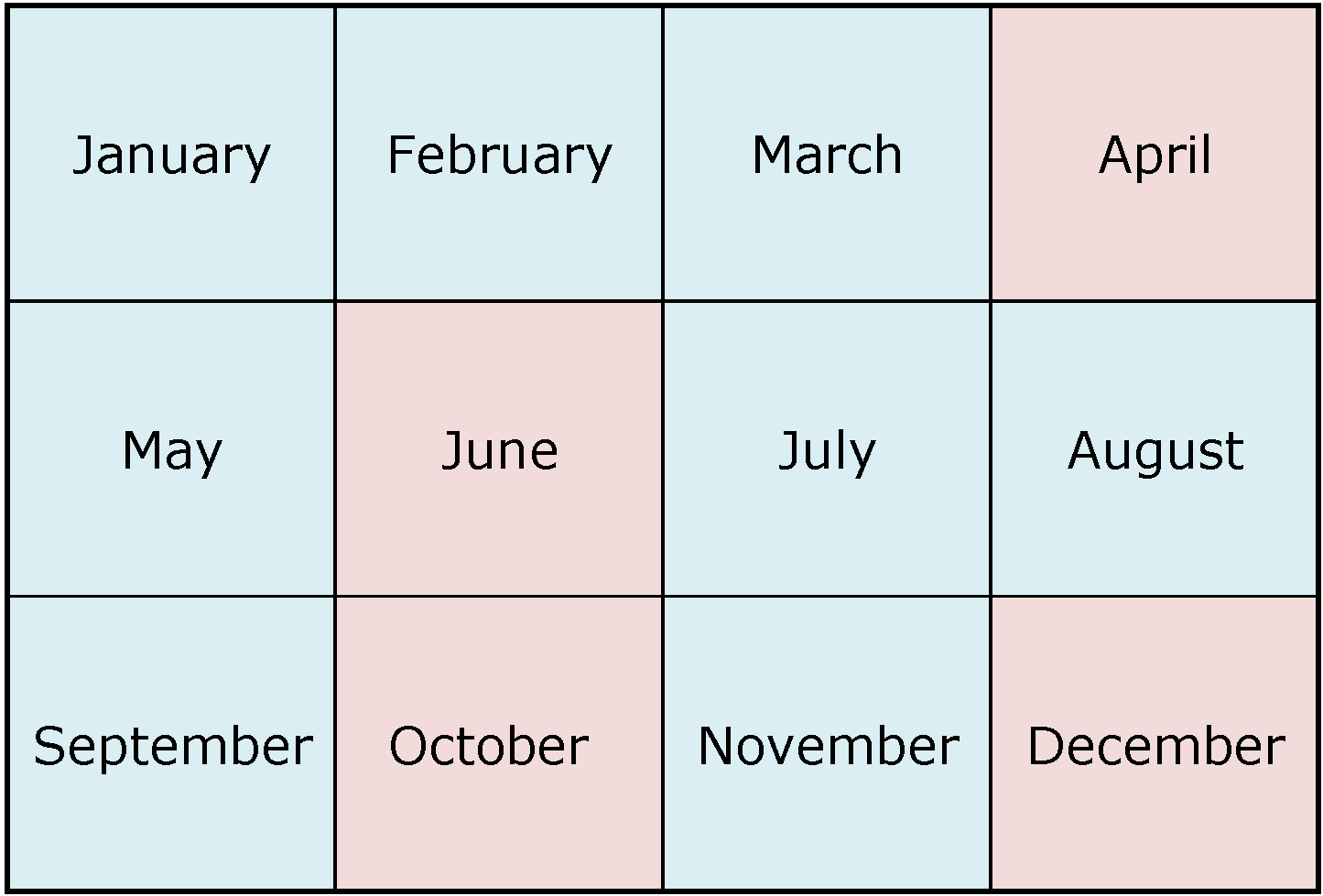

Next Issue will be published according the the calendar.

Next Issue will be published according the the calendar.