Published in Scientific Papers. Series "Management, Economic Engineering in Agriculture and rural development", Vol. 21 ISSUE 4

Written by Elsaied SEHSAH, Tarek FOUDA, Mohamed DARWESH, Nada ELDALY, Mayie AMER

The environmental contamination due to off-target deposition of pesticide droplets can be minimized by using optimum design and operating parameters of sprayers. The fabricated electric rotary cage atomizer manufactured from the following component, rugged stainless steel welded frame with protective air intake grate, the center axial fane, high strength fiberglass protective and DC electric motor. The motor rotating speed was 3500 rpm. The liquid distribution system consisted of a metal liquid feed channel with holes leading to a series of grooves on the insides of the vanes between the slots. The open-ended design allowed the cage to act as a small centrifugal fan. This paper describes a collaborative theoretical and experimental research effort to investigate the performance of developed electric rotary cage atomizer utilized in agricultural field specially to spray orchards. A three-dimensional computational fluid dynamics (CFD) model was developed and used to evaluate concepts of rotary cage atomizer sprayer setup to orchard spraying to reduce drift without a decrease in biological efficacy. The result indicated that the maximum power requirement for single and two rotary cage spryer atomizers were 29.76 W and 55.2 W at rotational speed 3,500 rpm respectively. The maximum air velocity was recorded 5.3 ms-1 at out let distance 20 cm and rotational speed 3,500 rpm. The values of droplet size D0.5 were 251.72 at operating condition 0.4 L min-1, 1,500 rpm and 0.5 ms-1 air velocity compared with droplet size D0.5 80.23 at operating condition 1.4 L min-1, 3,500 rpm and 5.3 ms-1 air velocity. The increasing of the air velocity (U), rotational speed (Ω) and liquid flow rate tends to decrease the droplet size D0.25, D0.5, and D0.75. The values of droplet size D0.5 were 251.72 at operating condition 0.4 L min-1, 1,500 rpm and 0.5 ms-1 air velocity compared with droplet size D0.5 80.23 at operating condition 1.4 L min-1, 3,500 rpm and 5.3 ms-1 air velocity.

[Read full article] [Citation]

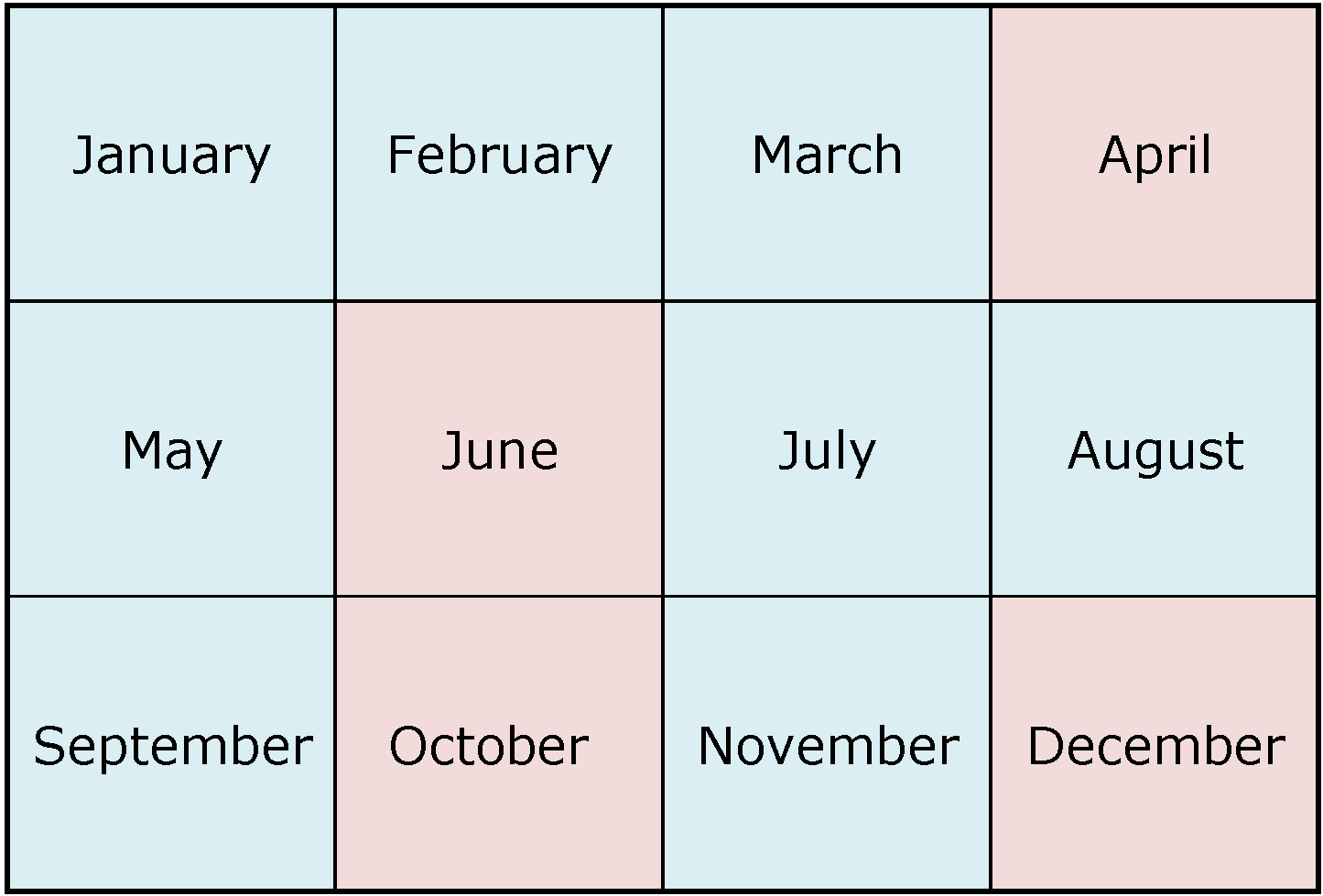

Next Issue will be published according the the calendar.

Next Issue will be published according the the calendar.